Aug . 25, 2025 00:40 Back to list

China Sterile Nylon Flocked Throat Swabs: Superior Sample Collection

Decoding the Evolution of Diagnostic Tools: China Sterile Throat Swab Nylon Flocked Technology

The global landscape of clinical diagnostics is continuously evolving, driven by the imperative for enhanced accuracy, efficiency, and patient safety. In this dynamic environment, the role of pre-analytical sample collection devices is paramount. Among these, the china sterile throat swab nylon flocked has emerged as a cornerstone technology, significantly improving diagnostic yield across a spectrum of infectious diseases. This article delves into the technical intricacies, application advantages, and market dynamics surrounding this critical medical device, offering a comprehensive resource for B2B decision-makers and technical professionals.

Industry trends indicate a sustained demand for high-performance sample collection tools, particularly in the wake of global health crises that have underscored the importance of rapid and reliable diagnostics. Flocked swabs, with their superior sample collection and elution capabilities, are increasingly replacing traditional fiber-wound swabs. The market is also seeing a shift towards automated processing compatibility and advanced sterilization methods, ensuring maximum safety and operational efficiency in high-throughput laboratory settings. As a leading sterile throat swab nylon flocked supplier, our focus remains on innovation that aligns with these critical industry requirements.

Technical Specifications and Parameters of Sterile Throat Swab Nylon Flocked

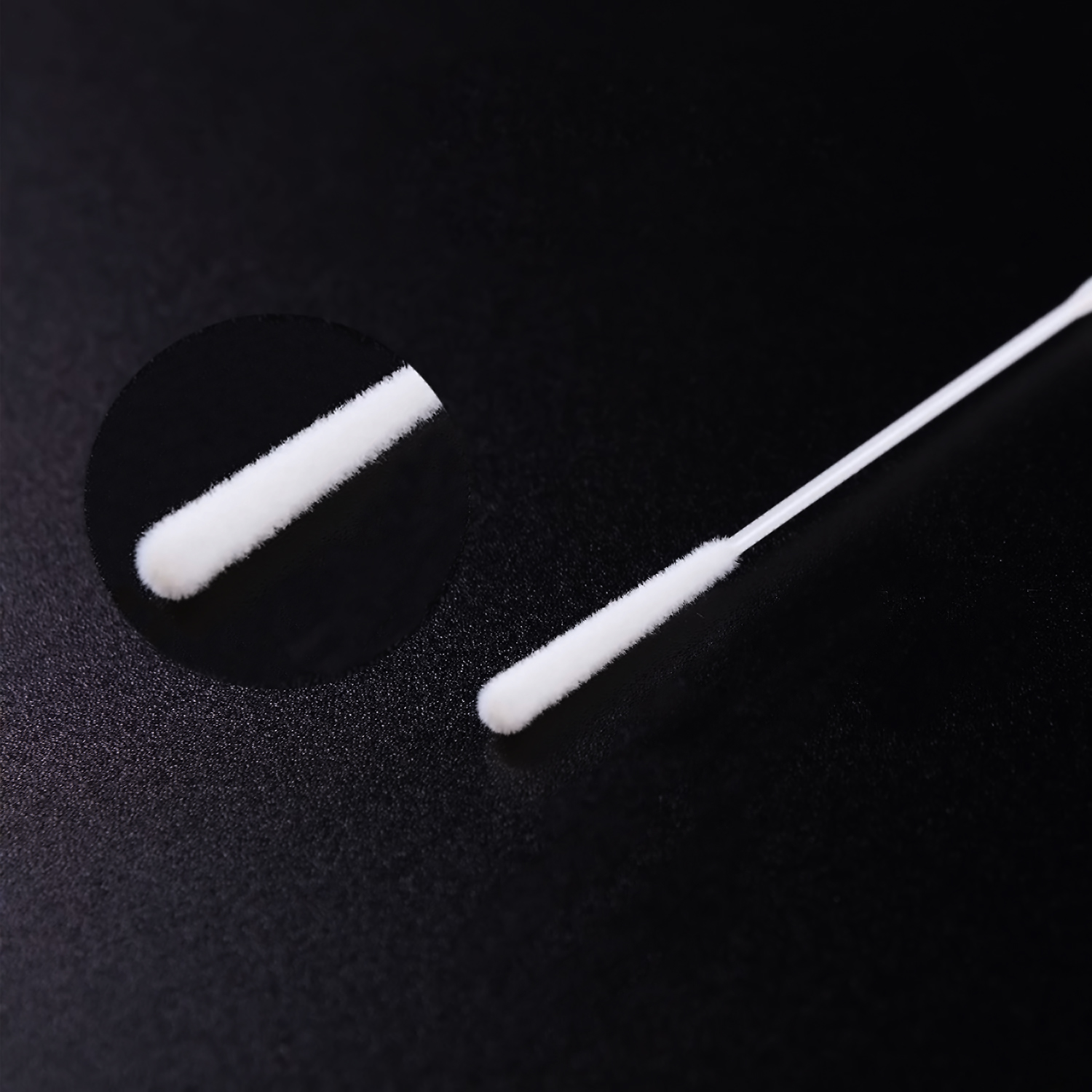

The efficacy of a sterile throat swab is determined by its design, material science, and manufacturing precision. A high-quality china sterile throat swab nylon flocked features a unique construction that optimizes sample uptake and release. Key components include a breakable polystyrene or polypropylene shaft and a flocked tip composed of short, perpendicular nylon fibers.

Core Material Science

- Shaft Material: Typically medical-grade polystyrene or polypropylene, engineered for optimal flexibility and a pre-molded break-point for safe sample transport.

- Flocked Tip: Composed of medical-grade nylon fibers electrostatically applied to the tip. This process creates a velvet-like texture, maximizing surface area for cell and viral particle collection.

- Adhesive: A non-toxic, medical-grade adhesive securely binds the nylon fibers to the shaft, ensuring fiber integrity during sample collection and elution.

Performance Parameters

Quantitative evaluation of these swabs includes metrics such as liquid absorption capacity, fiber retention, and compatibility with various transport media. The following table outlines typical specifications for a high-performance china sterile throat swab nylon flocked.

| Parameter | Specification | Standard/Test Method |

|---|---|---|

| Shaft Length | 150 mm (approx.) | Internal QA/QC |

| Tip Dimensions | 20 mm (L) x 5 mm (Dia.) (approx.) | Internal QA/QC |

| Break-point | 80 mm from tip (standard) | ISO 18369-3 |

| Sample Release Efficiency | ≥95% (compared to traditional swabs) | CDC SOP, Internal Validation |

| Sterilization Method | Gamma Irradiation (SAL 10-6) | ISO 11137 |

| Shelf Life | 3-5 years from manufacturing date | ISO 11607 |

| RNase/DNase Free | Certified | Internal QC, Molecular Grade Testing |

Application Scenarios and Target Industries

The versatility and high performance of the china sterile throat swab nylon flocked make it indispensable across a wide range of diagnostic and research applications. Its primary utility lies in the efficient collection of cellular and viral material from the oropharynx, nasopharynx, and other mucosal surfaces.

Key Application Areas:

- Infectious Disease Diagnostics: Widely used for sampling in PCR, RT-PCR, antigen detection, and culture tests for respiratory viruses (e.g., Influenza, RSV, SARS-CoV-2), bacterial pharyngitis (e.g., Group A Streptococcus), and other microbial infections.

- Forensic Science: For DNA collection from oral cavity samples.

- Environmental Monitoring: In certain niche applications, for collecting microbial samples from surfaces.

- Clinical Research: For cohort studies involving microbiome analysis or genetic screening.

Target Industries:

- Hospitals & Clinics: For routine patient diagnostics and screening programs.

- Diagnostic Laboratories: Central and reference labs, both private and public, processing high volumes of samples.

- Research Institutions: Universities and biotech companies conducting studies on infectious diseases and human genomics.

- Public Health Agencies: For surveillance, outbreak investigation, and community testing initiatives.

- Veterinary Medicine: For collecting samples from animals for infectious disease testing.

The application in energy saving, corrosion resistance, or similar industrial engineering contexts, as typically seen in petrochemical or metallurgy industries, is not directly relevant to sterile throat swabs. Instead, advantages are demonstrated in areas like improved diagnostic turnaround times, reduced false negatives, and enhanced compatibility with automated laboratory workflows, leading to significant operational efficiencies in healthcare and public health sectors.

Technical Advantages of Nylon Flocked Swabs

The technical superiority of the china sterile throat swab nylon flocked over traditional wound-fiber swabs is well-documented and widely recognized in clinical microbiology. These advantages translate directly into more reliable diagnostic outcomes and optimized laboratory processes.

Enhanced Sample Collection and Release

- Superior Sample Collection: The perpendicular orientation of nylon fibers, created through electrostatic flocking, acts like a soft brush, efficiently collecting a larger volume of cells and biological fluid. This contrasts sharply with traditional wound-fiber swabs, where fibers are haphazardly interwoven, trapping samples within the matrix.

- Optimized Sample Elution: Unlike cotton or rayon swabs, which can bind samples within their fibrous matrix, flocked swabs release nearly 95% of the collected sample rapidly and completely into the transport medium. This ensures maximal recovery of nucleic acids or antigens for downstream molecular assays, minimizing the risk of false-negative results.

Consistency and Reproducibility

- Reduced Inhibitors: The inert nature of nylon fibers and medical-grade plastics minimizes the presence of PCR inhibitors or substances that could interfere with diagnostic assays, ensuring cleaner samples.

- Standardized Design: Consistent manufacturing processes for china sterile throat swab nylon flocked products ensure uniform tip dimensions, fiber density, and shaft properties, leading to reproducible sample collection across different users and batches.

Safety and Ease of Use

- Ergonomic Design: Flexible shafts and defined break-points facilitate safe and comfortable sample collection, even from challenging anatomical sites, and ensure secure transfer into transport tubes.

- Sterility Assurance: Gamma irradiation provides a high Sterility Assurance Level (SAL 10-6), crucial for preventing contamination and ensuring patient safety and diagnostic integrity.

Manufacturing Process Flow for Sterile Throat Swab Nylon Flocked

The production of a china sterile throat swab nylon flocked is a meticulously controlled multi-stage process, critical for ensuring the final product meets stringent quality and sterility standards. This process leverages advanced manufacturing techniques to create a superior sample collection device.

Detailed Process Steps:

Step 1: Shaft Molding (Injection Molding)

Medical-grade polystyrene or polypropylene pellets are precisely heated and injected into molds to form the swab shafts. This process ensures dimensional accuracy and incorporates the pre-molded break-point. Quality control involves visual inspection and measurement against CAD specifications (ISO 13485). Target industries include medical device manufacturing.

Step 2: Adhesive Application

A thin, even layer of medical-grade, non-toxic adhesive is precisely applied to one end of the molded shaft. The adhesive formulation is crucial for secure fiber attachment and for not interfering with downstream assays. Adhesion strength is tested rigorously.

Step 3: Electrostatic Flocking

This is the core differentiating step. Short, high-purity nylon fibers are placed in an electrostatic field. The charged fibers align themselves perpendicularly and are propelled onto the adhesive-coated shaft tip, embedding themselves securely. This creates the characteristic velvet-like flocked surface, critical for high collection efficiency.

Step 4: Curing and Drying

The flocked swabs undergo a controlled curing process (e.g., in ovens) to permanently bond the nylon fibers to the shaft. This step ensures fiber retention and prevents shedding during use, which is critical for patient safety and sample integrity. Parameters like temperature and duration are tightly controlled.

Step 5: Quality Inspection (Automated & Manual)

Each swab undergoes stringent quality checks, including visual inspection for fiber density, uniformity, and absence of defects. Automated optical inspection systems are often employed for consistency. Key parameters checked include overall length, tip dimension, and break-point integrity, adhering to ISO 13485 standards.

Step 6: Packaging

Swabs are individually sealed in sterile peel-pouches or bulk packed, depending on customer requirements. Packaging materials are medical-grade, ensuring a sterile barrier. This step is performed in a cleanroom environment (e.g., Class 100,000) to prevent pre-sterilization contamination (ISO 14644-1).

Step 7: Sterilization

The packaged swabs are sterilized, typically using validated Gamma Irradiation (cobalt-60). This method ensures a Sterility Assurance Level (SAL) of 10-6, meaning less than one chance in a million of a non-sterile unit. Sterilization validation follows ISO 11137 guidelines. This ensures product readiness for sensitive medical applications. Expected service life (shelf life) is typically 3-5 years post-sterilization.

This rigorous process ensures that each sterile throat swab nylon flocked supplier product delivers consistent, reliable performance for critical diagnostic applications.

Vendor Comparison: Selecting Your Sterile Throat Swab Nylon Flocked Supplier

Choosing the right sterile throat swab nylon flocked supplier is a strategic decision that impacts diagnostic accuracy, operational efficiency, and cost-effectiveness. Key differentiators extend beyond mere pricing to encompass product quality, manufacturing compliance, and logistical capabilities.

Evaluation Criteria:

- Certifications: Look for ISO 13485 (Medical Devices Quality Management System), CE marking (for European market), and FDA registration (for US market).

- Manufacturing Standards: Adherence to GMP (Good Manufacturing Practices) and cleanroom production environments.

- Material Purity: Use of medical-grade, non-cytotoxic materials.

- Performance Data: Availability of validated data on sample collection/elution efficiency.

- Customization Capabilities: Ability to provide bespoke solutions (e.g., different shaft lengths, tip sizes, packaging).

- Supply Chain Reliability: Consistent lead times, robust logistics, and capacity to handle large orders.

- Technical Support: Responsiveness and expertise in addressing technical queries and providing post-sales support.

Product Comparison Table (Illustrative):

| Feature/Supplier | Our Product (Example) | Competitor A (Premium) | Competitor B (Economy) |

|---|---|---|---|

| Certifications | ISO 13485, CE, FDA Reg. | ISO 13485, CE, FDA Reg. | ISO 13485, CE |

| Sample Release Efficiency | ≥95% | ≥95% | ≥90% |

| Sterilization Method | Gamma Irradiation (SAL 10-6) | Gamma Irradiation (SAL 10-6) | EO Gas / Gamma (SAL 10-3) |

| Shaft Material | Medical-grade PS | Medical-grade PP | Standard PS |

| RNase/DNase Free | Yes, Certified | Yes, Certified | Generally Yes |

| Typical Price Point (per unit) | Mid-Range | High | Low |

Customized Solutions and Application Case Studies

Recognizing that no single solution fits all, a responsive sterile throat swab nylon flocked supplier offers customized solutions to meet specific client requirements, alongside documented application case studies that underscore practical efficacy.

Tailored Customization Options:

- Shaft Variations: Different lengths, diameters, and flexibilities can be manufactured to suit specific anatomical sampling needs or automated liquid handling systems.

- Tip Geometry: Custom tip shapes and sizes (e.g., smaller pediatric tips, larger oropharyngeal tips) can be developed.

- Break-Point Placement: Customized break-points on the shaft can optimize compatibility with specific transport tubes or automated decapping systems.

- Packaging Configurations: Options for individual peel-pouches, multi-pack sterile bags, or even integration with pre-filled transport media tubes.

- Branding and Labeling: Private labeling and customized packaging designs are available for OEM partners.

Real-World Application Case Studies:

Case Study 1: Large-Scale Respiratory Virus Screening Program

A national public health laboratory initiated a large-scale SARS-CoV-2 screening program requiring millions of sample collection kits. Our china sterile throat swab nylon flocked was selected due to its proven high viral load collection and elution efficiency, critical for minimizing false negatives in a high-volume testing environment. We provided a custom solution with a slightly longer shaft for nasopharyngeal collection and integrated it into a pre-filled VTM tube system. The consistent quality and reliable supply chain enabled the laboratory to process over 500,000 samples per week with high diagnostic accuracy, as reported by their internal quality metrics (CT values consistently lower than traditional swabs, indicating higher viral RNA yield).

Case Study 2: Pediatric Diagnostics for Bacterial Pharyngitis

A leading pediatric hospital sought to improve the comfort and efficacy of throat swab collection for Group A Streptococcus detection in young children. We developed a customized china sterile throat swab nylon flocked with a smaller, softer tip and a more flexible shaft, allowing for less invasive and more comfortable collection. The hospital reported a significant reduction in patient discomfort scores and an increase in positive yield rates (confirmed by culture) compared to their previous standard swabs, leading to quicker diagnoses and targeted antibiotic treatment, aligning with the hospital's patient-centered care initiatives.

Trustworthiness and Support: FAQ, Lead Time, Warranty, and Customer Service

Establishing and maintaining trust is paramount in the B2B medical device sector. Our commitment to transparency, reliability, and robust support ensures our clients receive not just products, but comprehensive solutions.

Frequently Asked Questions (FAQ):

- Q: Are your sterile throat swabs compatible with various Viral Transport Media (VTM) formulations?

A: Yes, our china sterile throat swab nylon flocked products are validated for compatibility with a wide range of commercially available VTMs and molecular transport media, ensuring optimal sample preservation and downstream assay performance.

- Q: What is the recommended storage condition for the swabs?

A: Our sterile swabs should be stored at room temperature (15-30°C) in their original sealed packaging, away from direct sunlight and moisture, to maintain sterility and material integrity throughout their stated shelf life.

- Q: Can these swabs be used for self-collection?

A: While the design is user-friendly, self-collection protocols must be validated by the end-user institution in accordance with local regulatory guidelines and professional medical advice. Our standard swabs are primarily designed for professional healthcare use.

- Q: How do you ensure product quality and batch consistency?

A: We operate under an ISO 13485 certified Quality Management System. Every production batch undergoes rigorous in-process and final quality control checks, including visual inspection, dimensional verification, fiber retention tests, and sterility confirmation (e.g., biological indicator testing for gamma irradiation). Traceability records are maintained for each batch.

Lead Time and Fulfillment Details:

Standard lead times for our china sterile throat swab nylon flocked products typically range from 2-4 weeks for regular stock orders, depending on order volume and current production schedules. For large-volume or customized orders, lead times will be communicated explicitly after project scope definition. We maintain robust inventory levels of raw materials and finished goods to mitigate supply chain disruptions and offer expedited shipping options where urgent needs arise.

Warranty Commitments:

All our sterile throat swabs are warranted to be free from defects in material and workmanship for the duration of their stated shelf life, provided they are stored and used according to recommended guidelines. This warranty covers manufacturing defects and sterility assurance. In the unlikely event of a quality concern, we commit to swift investigation, root cause analysis, and appropriate resolution, including replacement of defective products.

Customer Support and After-Sales Service:

Our dedicated customer support team and technical specialists are available to assist with product inquiries, order placement, and technical support. We provide comprehensive documentation, including Certificates of Analysis, technical datasheets, and regulatory compliance records. For any post-sales queries or support requirements, clients can reach us via phone, email, or through our online portal. We pride ourselves on responsive and knowledgeable assistance, ensuring seamless integration and optimal performance of our products within your operations.

Conclusion

The china sterile throat swab nylon flocked represents a pivotal advancement in diagnostic sample collection technology. Its unique design and manufacturing precision offer unparalleled advantages in terms of sample collection efficiency, elution rates, and overall diagnostic reliability. As a trusted sterile throat swab nylon flocked supplier, we are committed to upholding the highest standards of quality, innovation, and customer support, ensuring that our partners in healthcare and research are equipped with the best tools to meet their critical diagnostic needs. By understanding the intricate process flow, adhering to rigorous technical specifications, and leveraging customized solutions, institutions can enhance their diagnostic capabilities and contribute significantly to public health outcomes.

Citations:

- World Health Organization. Laboratory testing for coronavirus disease 2019 (COVID-19) in suspected human cases. Interim guidance, 2020.

- Centers for Disease Control and Prevention. Interim Guidelines for Collecting, Handling, and Testing Clinical Specimens for COVID-19.

- Nolte, F. S., & Tang, Y. W. (2018). Molecular microbiology: diagnostic principles and practice. ASM Press.

- ISO 13485:2016. Medical devices—Quality management systems—Requirements for regulatory purposes. International Organization for Standardization.

- ISO 11137-1:2006. Sterilization of health care products—Radiation—Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices. International Organization for Standardization.

-

Accurate Benzodiazepines (BZO) Rapid Test Kits | Fast Results

NewsAug.27,2025

-

Trusted Early Pregnancy Test Kit Supplier | Accurate, Fast Results

NewsAug.26,2025

-

China Sterile Nylon Flocked Throat Swabs: Superior Sample Collection

NewsAug.25,2025

-

COVID-19 Rapid Antigen Test Kit: Accurate & Fast Home Results

NewsAug.24,2025

-

Premium Cassette Lateral Flow Devices for Rapid Diagnostics

NewsAug.23,2025

-

Pregnancy Test Calculator: Know Your Weeks, Week by Week

NewsAug.22,2025