Sep . 22, 2024 21:29 Back to list

buy typhoid test cost manufacturer

Understanding the Cost Factors of Typhoid Test Kits from Manufacturers

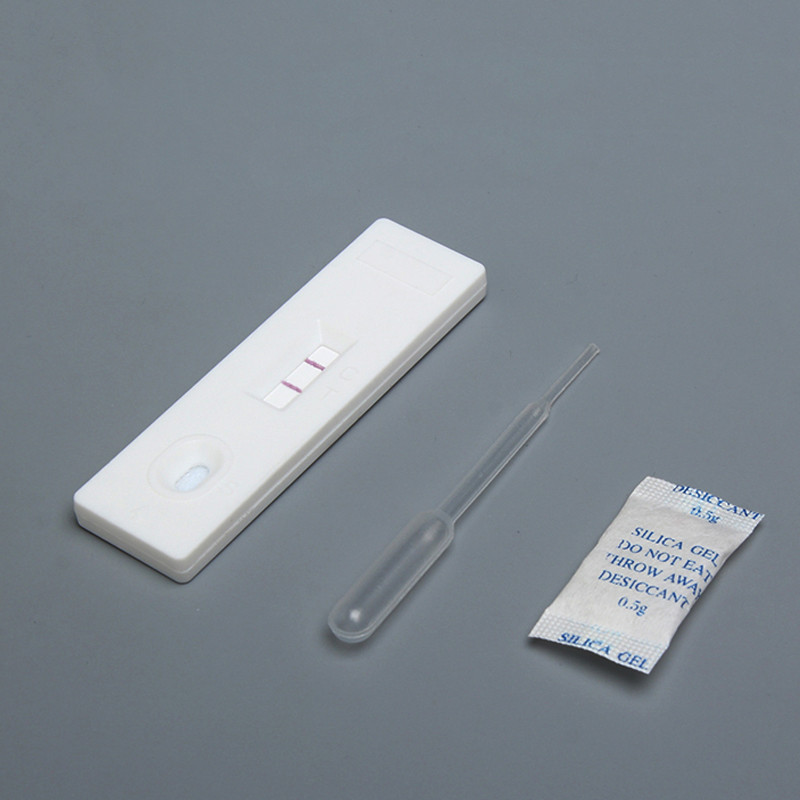

Typhoid fever, caused by the bacterium Salmonella enterica serotype Typhi, remains a significant health concern in many parts of the world. Accurate and timely diagnosis is essential for effective treatment and control of the disease. As a result, the demand for reliable typhoid test kits has surged, prompting various manufacturers to develop and produce these essential diagnostic tools. When considering the purchase of typhoid test kits, understanding the associated costs and the factors influencing them is vital for healthcare providers, laboratories, and organizations.

Types of Typhoid Tests

There are mainly two types of tests available serological tests and molecular tests. Serological tests, which detect antibodies in a patient's blood, are generally more affordable but may yield false positives. On the other hand, molecular tests, such as polymerase chain reaction (PCR) tests, are more accurate but tend to be pricier. The choice of test directly influences the cost, with manufacturers pricing their products based on the technology used, the materials required, and the complexity of the testing procedure.

Cost Breakdown

1. Manufacturing Process The cost of raw materials, research and development, and labor significantly contributes to the final price of the test kits. Established manufacturers with efficient production processes often offer competitive prices. Furthermore, manufacturers who invest in advanced technology typically produce more reliable tests, which may come at a higher cost.

buy typhoid test cost manufacturer

2. Regulatory Compliance Different regions have specific regulatory requirements for medical devices, including typhoid test kits. Manufacturers must comply with guidelines set by health authorities, leading to additional costs. These regulatory processes often involve extensive testing, quality control, and certification, which can be reflected in the retail price of the kits.

3. Volume and Scale Purchasing in larger quantities can result in significant cost savings. Manufacturers frequently offer bulk discounts for larger orders, which can be beneficial for hospitals, clinics, and public health organizations looking to stock up on essential diagnostic tools.

4. Market Competition The presence of multiple manufacturers in the market creates competition, which can drive prices down. However, it’s essential to balance cost with quality. Not all test kits on the market will offer the same level of accuracy and reliability.

5. Shipping and Logistics The cost of shipping and managing logistics also plays a role. For remote areas or regions where healthcare supplies are challenging to access, transportation costs can increase the overall price of the typhoid test kits.

Conclusion

When considering the purchase of typhoid test kits, it is crucial to assess not just the unit price but also the factors influencing these costs. By understanding the different elements—such as manufacturing processes, regulatory compliance, scale of purchase, market competition, and logistical challenges—organizations can make informed decisions that balance both cost and the quality of the diagnostic tools. Investing in reliable and accurate test kits can ultimately lead to better health outcomes in the fight against typhoid fever.

-

Malaria Pf Ag Rapid Test Kit - Quick & Accurate Detection

NewsAug.11,2025

-

Accurate Cardiac Marker CK-MB Rapid Test for Quick Results

NewsAug.10,2025

-

Premium Empty ABS Plastic Cassette for Test Strips

NewsAug.09,2025

-

Sterile Urine Cup: Accurate Specimen Collection for Labs & Home

NewsAug.08,2025

-

Malaria Pf/Pan Ag Rapid Test Kit for Fast, Accurate Diagnosis

NewsAug.07,2025

-

Rapid Canine Corona Test: Fast & Accurate Results

NewsAug.06,2025