Dec . 09, 2024 15:46 Back to list

typhoid test cost factory

Understanding the Cost of Typhoid Testing in Factory Settings

Typhoid fever, a severe and sometimes fatal illness caused by the *Salmonella enterica* serotype Typhi, poses a significant health threat, especially in regions with inadequate sanitation and hygiene. For industries, particularly those in food processing, pharmaceuticals, or any sector where health standards are paramount, the cost of typhoid testing becomes a critical factor in safeguarding public health and ensuring compliance with legal regulations. This article delves into the various aspects influencing the cost of typhoid testing in factory settings.

The Importance of Typhoid Testing

Typhoid fever remains a significant concern in many developing countries, leading to serious health complications if left untreated. Factories with employees who are in constant contact with food products or who work in environments where pathogens can spread rapidly must prioritize health checks, including typhoid testing. Regular screening can help prevent outbreaks that not only jeopardize employee health but also tarnish a company's reputation and lead to financial losses.

Breakdown of Typhoid Testing Costs

The costs associated with typhoid testing in a factory setup can be categorized into a few key areas

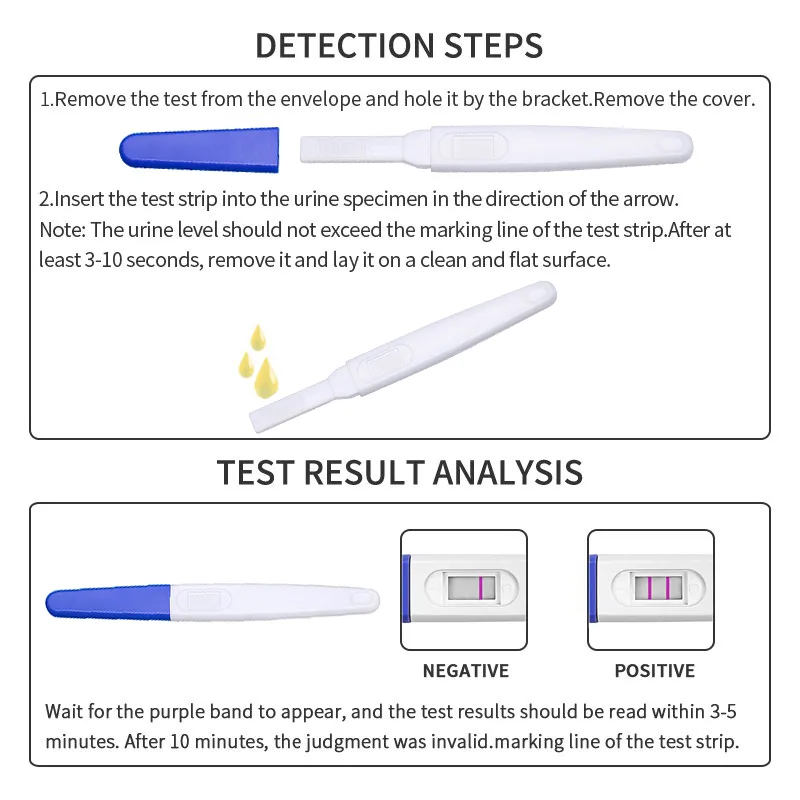

1. Test Kit and Reagent Costs One of the primary expenses includes purchasing test kits, which come in various forms such as blood tests, stool tests, or urine tests. The price of these kits can vary significantly based on their sensitivity and specificity. Typically, the more accurate and reliable the test, the higher the cost.

2. Laboratory Fees If factories outsource testing to external laboratories, there will be additional costs associated with sample collection, transport, and test processing. Pricing structures can vary, with some labs offering bulk testing rates that may reduce individual test costs.

3. Personnel Training and Labor Factories need to ensure that staff members are adequately trained in sample collection and handling. This may involve hiring trained medical personnel or providing training for current employees, adding to the overall cost.

typhoid test cost factory

4. Infrastructure and Maintenance Factories may require specific infrastructure to carry out testing onsite, including setting up sterile environments or purchasing equipment for sample processing. The costs associated with creating and maintaining such facilities can be considerable.

5. Initial Screening vs. Ongoing Monitoring Costs also differ depending on whether the testing is a one-off screening for new employees or part of an ongoing health monitoring program. Continuous monitoring requires regular budget allocation, whereas a one-time screening might involve a larger upfront cost.

Factors Influencing Cost Variability

Several factors can affect the overall cost of typhoid testing

- Geographic Location The availability and cost of medical supplies and laboratory services can vary by region, impacting how much factories spend on testing. - Regulatory Requirements Local health regulations may mandate specific testing protocols. Factories might need to comply with strict testing frequencies, influencing overall costs.

- Outbreak Responses If there is a reported outbreak of typhoid near a factory, the company may incur additional costs for emergency testing and implementing health protocols.

- Volume of Testing Larger factories with more employees may benefit from economies of scale, reducing the cost per test. In contrast, smaller operations might face higher per-test costs.

Conclusion

Investing in typhoid testing is not merely a compliance measure but a critical component of safeguarding employee health and public safety. Though the costs can vary widely based on multiple factors—such as test types, laboratory fees, and training requirements—the long-term benefits of preventing disease outbreaks far outweigh the expenses involved. Factories must approach their health policies with foresight, ensuring they protect both their workers and their bottom line while contributing to the broader goal of public health. In an age where health standards are under constant scrutiny, proactive measures like typhoid testing are essential not only for operational integrity but also for building consumer trust and maintaining a robust workforce.

-

Accurate Benzodiazepines (BZO) Rapid Test Kits | Fast Results

NewsAug.27,2025

-

Trusted Early Pregnancy Test Kit Supplier | Accurate, Fast Results

NewsAug.26,2025

-

China Sterile Nylon Flocked Throat Swabs: Superior Sample Collection

NewsAug.25,2025

-

COVID-19 Rapid Antigen Test Kit: Accurate & Fast Home Results

NewsAug.24,2025

-

Premium Cassette Lateral Flow Devices for Rapid Diagnostics

NewsAug.23,2025

-

Pregnancy Test Calculator: Know Your Weeks, Week by Week

NewsAug.22,2025