Agosti . 08, 2025 00:40 Back to list

Sterile Urine Cup: Accurate Specimen Collection for Labs & Home

The Unseen Hero in Diagnostics: Ensuring Precision with the Sterile Urine Cup

In the vast landscape of medical diagnostics, the integrity of a sample is paramount. From routine health check-ups to critical disease detection, the accuracy of laboratory results hinges significantly on the quality of the specimen collected. Among the myriad of collection devices, the **sterile urine cup** stands out as a fundamental tool, often overlooked yet indispensable. This comprehensive guide delves into the world of **urine collection cup** technology, exploring industry trends, technical intricacies, application scenarios, and the meticulous manufacturing processes that guarantee their reliability.

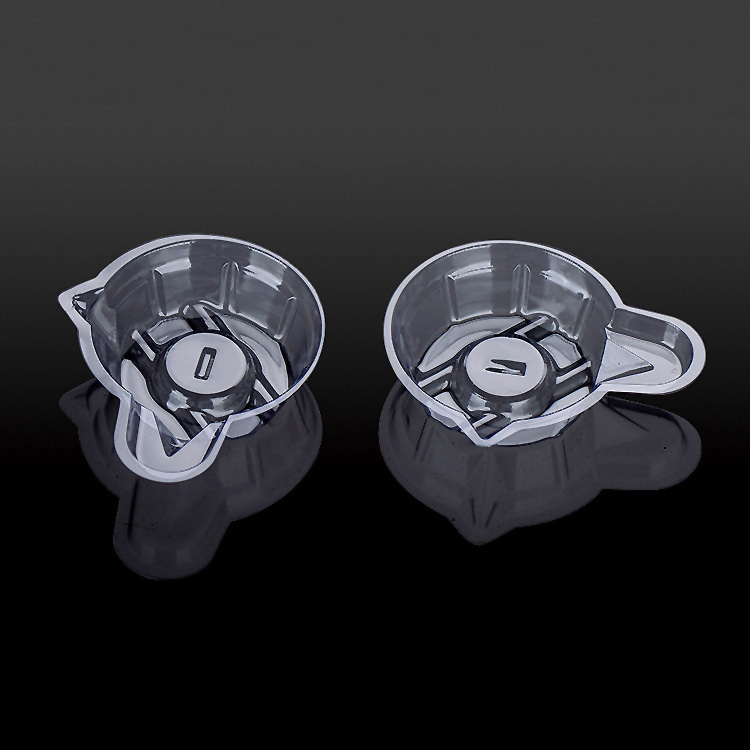

Product Spotlight: Sterile PVC Disposable Urine Cup

This article specifically highlights the advancements and critical role of the Sterile PVC Disposable Urine Cup, a product engineered for optimal sample integrity and user safety in diverse healthcare settings.

Industry Trends and the Growing Demand for Sterile Solutions

The global in-vitro diagnostics (IVD) market is experiencing robust growth, driven by an aging population, rising prevalence of chronic diseases, and increased awareness regarding early diagnosis. Within this market, the demand for high-quality, sterile sample collection devices like the sterile urine cup is escalating. Key trends include:

- Enhanced Sterility Assurance: A zero-tolerance approach to contamination, leading to stricter sterilization protocols and higher Sterility Assurance Levels (SALs).

- Material Innovation: Development of inert, non-reactive materials (like medical-grade PVC) that do not interfere with sample composition or analytical tests.

- User-Friendly Design: Focus on ergonomic designs for ease of use by both patients and healthcare professionals, including features like wide openings, secure caps, and clear graduation marks.

- Traceability and Compliance: Increased emphasis on tracking capabilities and adherence to international regulatory standards (e.g., FDA, CE, ISO 13485) to ensure product safety and efficacy.

- Sustainability Considerations: While disposability is key, manufacturers are exploring more sustainable materials and recycling options where feasible, without compromising sterility.

According to a report by Grand View Research, the global In-Vitro Diagnostics (IVD) market size was valued at USD 84.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth directly translates to a burgeoning need for reliable collection tools like the **urine specimen cups**.

Technical Advantages of the Sterile PVC Disposable Urine Cup

The PrisesBio Sterile PVC Disposable Urine Cup is engineered to meet the stringent requirements of modern diagnostics, offering distinct advantages:

- Superior Material Integrity:

- Medical-Grade PVC: Polyvinyl Chloride (PVC) is chosen for its excellent clarity, allowing visual inspection of the sample; its chemical inertness, ensuring no leaching or interaction with urine components; and its flexibility, which contributes to break resistance. It is also cost-effective, making sterile collection accessible.

- Non-Cytotoxic: Rigorously tested to ensure it does not harm cells or interfere with cellular assays, crucial for urinalysis and cytology.

- Assured Sterility (Sterility Assurance Level - SAL 10-6):

- Ethylene Oxide (EO) Sterilization: The cups undergo a validated Ethylene Oxide (EO) sterilization process, providing a Sterility Assurance Level (SAL) of 10-6. This means there is less than a one-in-a-million chance of a non-sterile unit. EO is highly effective against a broad spectrum of microorganisms, including bacteria, viruses, fungi, and spores, without compromising the integrity of the plastic material.

- Individual Packaging: Each **sterile urine cup** is individually packaged in a peel-pouch or sealed bag, maintaining sterility until the point of use and preventing cross-contamination.

- Leak-Proof Design:

- Secure Screw Cap: Features a tightly fitting screw cap with a robust thread design, creating a hermetic seal. This prevents leaks during collection, transport, and storage, safeguarding both the sample integrity and the safety of handlers.

- Wide Mouth Opening: Designed for easy and hygienic sample collection, minimizing spills and splashes.

- Accurate Volume Measurement:

- Clear Graduation Marks: Embossed or printed graduation lines (e.g., 20ml to 120ml or 25ml to 100ml) provide accurate volume indicators, essential for quantitative analysis in the lab.

- Durability and Longevity:

- Robust Construction: Despite being disposable, the cups are designed to withstand typical handling stresses without cracking or deforming.

- Extended Shelf Life: Typically, a **sterile urine cup** has a shelf life of 3-5 years from the date of manufacture when stored under recommended conditions, ensuring long-term usability for healthcare facilities.

The Meticulous Manufacturing Process of a Sterile Urine Cup

The production of a high-quality sterile urine cup is a highly controlled and sophisticated process, adhering to stringent quality management systems like ISO 13485. The goal is to produce a consistent, sterile, and reliable product. While specific machinery may vary, the general workflow involves:

Manufacturing Process Flow:

- Raw Material Sourcing & Inspection:

High-purity, medical-grade PVC resin pellets are sourced from certified suppliers. Upon arrival, these raw materials undergo rigorous quality control checks (e.g., Fourier-transform infrared spectroscopy (FTIR) for material identification, differential scanning calorimetry (DSC) for thermal properties, and heavy metal testing) to ensure compliance with pharmacopoeia standards (e.g., USP Class VI for biocompatibility) and regulatory requirements.

- Injection Molding (Cup Body & Cap):

The PVC pellets are fed into a precision injection molding machine. Inside the machine, the resin is heated to a molten state and then injected under high pressure into precisely engineered molds. This process is typically performed in an ISO Class 7 or 8 cleanroom environment to minimize particulate contamination. Critical parameters like temperature, injection pressure, and cooling time are meticulously controlled to ensure dimensional accuracy, clarity, and structural integrity of both the cup body and its cap.

(Schematic representation of injection molding process can be visualized as: Raw Pellets -> Heating Unit -> Injection Unit -> Mold Cavity -> Cooling -> Ejection of Part)

- Cooling & Deburring:

After molding, the parts are rapidly cooled within the mold to solidify. Once ejected, any minor flash (excess material) is precisely removed, ensuring smooth edges and a clean finish. This step is crucial for preventing potential cuts or discomfort during handling.

- Assembly (Cap & Cup):

The molded cup bodies and caps are then transported, usually via automated conveyors within the cleanroom, to an assembly station. Here, automated systems precisely fit the caps onto the cups or prepare them for final packaging. This stage may include the insertion of specific features like seals if required by design.

- In-Process Quality Control (QC):

Throughout the molding and assembly stages, continuous in-process QC checks are performed. This includes:

- Visual Inspection: Checking for defects such as cracks, deformities, discoloration, or foreign particles.

- Dimensional Verification: Using calipers and gauges to ensure precise dimensions, capacity, and cap fit.

- Leak Testing: Samples are periodically subjected to pressure tests to confirm the integrity of the seal between the cup and cap.

- Functional Testing: Assessing ease of opening/closing, and clarity of graduation marks.

- Individual Packaging:

Each **urine collection cup** is individually packaged in a medical-grade barrier pouch (typically a combination of paper and plastic film) within a cleanroom. This primary packaging is designed to maintain sterility and protect the product from environmental contaminants until it is opened for use. Automated packaging machines ensure consistent sealing and labeling.

- Sterilization:

The individually packaged cups are then transferred to a validated sterilization facility. As mentioned, Ethylene Oxide (EO) sterilization is a common method for these products. The process involves controlled exposure to EO gas under specific conditions of temperature, humidity, and gas concentration for a defined duration. Post-sterilization, a crucial aeration phase removes residual EO gas to safe levels, adhering to ISO 11135 standards for EO sterilization of healthcare products.

- Post-Sterilization & Final Inspection:

After sterilization, batch release testing is performed. This includes:

- Sterility Testing: (USP Sterility Tests) Samples from each sterilization batch are cultured in growth media to confirm the absence of microbial growth, verifying the SAL of 10-6.

- Residual EO Testing: (ISO 10993-7) To ensure EO residuals are below permissible limits for patient safety.

- Pyrogen Testing: (USP Pyrogen Test) To ensure the absence of bacterial endotoxins.

- Biological Reactivity Tests: (USP Biological Reactivity Tests, In Vitro and USP Biological Reactivity Tests, In Vivo) To confirm biocompatibility.

Only after all tests pass are the batches released for distribution.

- Warehousing & Distribution:

Finished products are stored in a controlled environment to maintain their integrity before being shipped to healthcare providers and laboratories worldwide.

This stringent process, from raw material to final sterile product, underscores the commitment to delivering a reliable **urine specimen cup** that healthcare professionals can trust for accurate diagnostic results.

Technical Parameters and Product Specifications

When selecting a sterile urine cup, understanding its technical specifications is crucial. Here's a typical parameter table for a high-quality product like PrisesBio's:

| Parameter | Specification (PrisesBio Sterile PVC Disposable Urine Cup) | Significance |

|---|---|---|

| Material | Medical-Grade PVC (Polyvinyl Chloride) | Ensures chemical inertness, optical clarity, flexibility, and non-toxicity. Free from Latex, DEHP. |

| Capacity | 100ml / 120ml (or as per variant) | Standard volumes for routine urinalysis, preventing overfill and sample dilution. |

| Sterilization Method | Ethylene Oxide (EO) | Validated method ensuring broad-spectrum microbial inactivation to SAL 10-6. |

| Sterility Assurance Level (SAL) | 10-6 | Industry standard for sterile medical devices, meaning less than one in a million chance of a non-sterile unit. |

| Cap Type | Leak-Proof Screw Cap | Provides a secure, airtight, and liquid-tight seal, crucial for preventing spills and contamination during transport. |

| Graduation Marks | Clear, molded/printed increments (e.g., 20ml to 120ml) | Facilitates accurate volume measurement for laboratory analysis. |

| Individual Packaging | Medical-Grade Peel Pouch | Maintains sterility until the point of use, protects from environmental contaminants. |

| Shelf Life | 3-5 Years (when stored properly) | Ensures product stability and usability over an extended period. |

| Regulatory Compliance | ISO 13485, CE Marked, FDA Registered (if applicable) | Adherence to international quality management and safety standards for medical devices. |

| Dimensions (Approx.) | Height: 70-80mm; Diameter: 55-65mm | Ergonomic for handling, compatible with standard laboratory racks and centrifuges. |

Comparison: Sterile vs. Non-Sterile Urine Collection Cups

The choice between a **sterile urine cup** and a non-sterile one profoundly impacts diagnostic accuracy, particularly for microbiological cultures. Here's a quick comparison:

| Feature | Sterile Urine Cup | Non-Sterile Urine Collection Cup |

|---|---|---|

| Intended Use | Urine culture & sensitivity, microbiological analysis, any test requiring aseptic sample. | Routine urinalysis (dipstick), general chemical tests, drug screening where bacterial contamination is less critical. |

| Sterility Assurance | Guaranteed sterile (e.g., SAL 10-6), free from viable microorganisms. | Not sterile; may contain environmental microorganisms. |

| Risk of Contamination | Extremely low risk of extrinsic contamination impacting test results. | High risk of introducing environmental bacteria, leading to false positives in cultures. |

| Manufacturing Environment | Cleanroom (ISO Class 7/8) controlled environment. | Standard manufacturing environment. |

| Packaging | Individually sealed, often in medical-grade pouches. | Bulk packed, often in bags. |

| Cost | Higher due to sterilization and cleanroom manufacturing. | Lower. |

| Regulatory Standards | More stringent, often requires ISO 13485, FDA, CE for sterile devices. | Less stringent for general labware. |

Application Scenarios and Industry Benefits

The Sterile PVC Disposable Urine Cup is essential across a wide range of healthcare and laboratory settings:

- Clinical Laboratories: The primary user, ensuring accurate results for urinalysis, microscopy, and most critically, urine cultures for detecting urinary tract infections (UTIs). Without a sterile cup, distinguishing true infection from sample contamination is impossible, leading to misdiagnosis or inappropriate antibiotic prescriptions.

- Hospitals & Clinics: Used for inpatient and outpatient sample collection, supporting rapid and reliable diagnosis at the point of care.

- Physician's Offices: For in-house testing or preparation of samples for external laboratories.

- Research Facilities: In studies requiring pristine biological samples, particularly in microbiology, pathology, and toxicology research.

- Emergency Rooms: Critical for quick and uncontaminated sample collection in urgent diagnostic situations.

- Home Health & Patient Self-Collection: Designed for ease of use, enabling patients to collect samples hygienically at home, then transport them safely to a lab. This contributes to patient comfort and adherence.

Benefits in Application:

- Enhanced Diagnostic Accuracy: By preventing external contamination, **sterile urine cup** significantly reduces the incidence of false positive urine culture results, leading to more accurate diagnoses and targeted treatment. This saves healthcare costs by avoiding unnecessary antibiotic prescriptions and repeat tests.

- Improved Patient Safety: Minimizes the risk of biohazard exposure to healthcare workers and patients through its leak-proof design during collection and transport.

- Operational Efficiency: Standardized, easy-to-use design streamlines sample collection workflows in busy clinical environments.

- Reduced Healthcare Costs: While individually more expensive than non-sterile alternatives, the prevention of erroneous results and subsequent unnecessary treatments, along with simplified lab processes, can lead to significant overall cost savings for the healthcare system.

Choosing Your Partner: Manufacturer Comparison and PrisesBio's Edge

Selecting the right manufacturer for **urine specimen cups** is as critical as the product itself. Key considerations include:

- Quality Management Systems: Is the manufacturer ISO 13485 certified? This ensures a robust quality management system for medical device manufacturing.

- Regulatory Compliance: Are their products FDA registered, CE marked, and compliant with other relevant regional regulations?

- Manufacturing Expertise: Do they possess extensive experience in cleanroom manufacturing and sterilization processes?

- Research & Development: Are they continually innovating and improving their product designs and materials?

- Supply Chain Reliability: Can they ensure consistent supply and timely delivery, especially crucial for high-volume demand?

- Customer Support: Do they offer responsive technical support and reliable post-sales service?

PrisesBio, as a dedicated manufacturer in the medical device sector, distinguishes itself through a steadfast commitment to these principles:

- Proven Track Record: With years of experience in producing high-quality medical consumables, PrisesBio has established a reputation for reliability and excellence.

- Certifications & Compliance: PrisesBio products, including the Sterile PVC Disposable Urine Cup, adhere to international standards such as ISO 13485:2016 for Medical Devices Quality Management Systems, CE marking for European markets, and are registered with the FDA for the US market where applicable. This demonstrates unwavering commitment to global safety and quality benchmarks.

- Advanced Manufacturing: Utilizing state-of-the-art cleanroom facilities and automated production lines, PrisesBio minimizes human intervention and environmental contamination, ensuring consistent product quality and sterility.

- Dedicated R&D: Continuous investment in R&D ensures products meet evolving industry needs and technological advancements.

- Global Supply Chain: Robust logistics and supply chain management ensure that products reach clients efficiently worldwide, guaranteeing an uninterrupted supply for critical healthcare operations.

- Customer-Centric Approach: PrisesBio prides itself on offering comprehensive customer support, from technical inquiries to order fulfillment and after-sales service, building long-term partnerships based on trust and mutual success.

Customization Solutions for Unique Requirements

While standard **sterile urine cup** designs meet most needs, healthcare institutions and research facilities often have specific requirements. PrisesBio offers flexible customization options to cater to diverse demands:

- Volume Capacities: Custom volumes beyond standard 100ml/120ml to suit specific testing protocols.

- Cap Variations: Different cap designs (e.g., snap-on, specialized transfer devices) or colors for easy identification.

- Labeling & Branding: Private labeling, custom printing, or specific barcode applications for seamless integration into existing hospital or lab inventory systems.

- Packaging Configurations: Bulk sterile packs, specific quantities per sleeve/box, or unique tray configurations for automated systems.

- Material Alternatives: While PVC is standard, options for other medical-grade polymers (e.g., Polypropylene - PP, Polystyrene - PS) can be explored for specific chemical compatibility or transparency needs, though this would alter the product name and specific properties. For example, PP offers superior chemical resistance to some solvents.

- Integrated Features: Development of cups with integrated features such as temperature strips, preservative additives, or vacuum transfer systems upon large-scale request and feasibility assessment.

These customization capabilities highlight the manufacturer's adaptability and commitment to providing tailored solutions that enhance efficiency and accuracy for various medical applications.

Real-World Application Cases and Customer Experience

The impact of a reliable **sterile urine cup** is best understood through its practical application and the feedback from users. PrisesBio has a history of successful deployments:

- Major Hospital Network Case Study: A large hospital network in Europe faced challenges with high rates of false-positive urine cultures, leading to unnecessary antibiotic prescriptions and increased healthcare costs. After implementing PrisesBio's Sterile PVC Disposable Urine Cup, they reported a significant 25% reduction in contamination rates over six months. This led to more accurate diagnoses, optimized antibiotic stewardship, and an estimated annual saving of €50,000 in lab re-testing and medication costs.

- Reference Laboratory Integration: A leading national reference laboratory adopted PrisesBio's cups for all their microbiology sample intake. Their feedback highlighted the consistent quality, reliable sterility, and the robust leak-proof design as key factors that improved their workflow efficiency and sample integrity from collection to analysis. The standardized design also seamlessly integrated with their automated processing lines.

- Home Health Care Provider Feedback: A rapidly expanding home healthcare provider praised the user-friendly design of the cups, which facilitated easy self-collection for patients. The secure cap ensured safe transport of samples from patient homes to processing centers, enhancing patient compliance and reducing logistical issues.

These examples underscore the tangible benefits of choosing a meticulously manufactured **sterile urine cup** – from enhanced diagnostic precision and operational efficiency to significant cost savings and improved patient outcomes.

Ensuring Trustworthiness: Quality Assurance & Customer Support

Trust is the bedrock of any medical product. PrisesBio fosters this trust through:

- Rigorous Quality Assurance: Every batch undergoes extensive testing, including sterility tests (conforming to USP ), endotoxin testing (USP ), and physical integrity tests. Our quality management system (QMS) is certified to ISO 13485:2016, ensuring consistent compliance with global medical device regulations.

- Delivery Cycle: Standard orders for the Sterile PVC Disposable Urine Cup are typically processed and shipped within 2-4 weeks, depending on quantity and destination. Urgent requirements can often be accommodated through expedited shipping options.

- Warranty Commitment: PrisesBio stands behind its products with a comprehensive warranty against manufacturing defects. Products are guaranteed to meet stated specifications and sterility claims for their entire shelf life when stored and used as directed.

- Customer Support: A dedicated team of product specialists and customer service representatives is available to assist with technical queries, order tracking, and any post-purchase support. We aim for prompt and effective resolution of any client concerns.

Frequently Asked Questions (FAQs) about the Sterile Urine Cup

1. What is the significance of "sterile" for a **urine cup**?

"Sterile" means the **urine cup** is free from all viable microorganisms (bacteria, viruses, fungi, spores). For urine collection, this is critical for microbiological testing (like urine cultures) because it prevents external contaminants from affecting the sample. If a non-sterile cup is used for a culture, environmental bacteria present in the cup could grow in the culture, leading to a false-positive result and potentially unnecessary antibiotic treatment.

2. What material is used for the Sterile PVC Disposable Urine Cup and why?

The PrisesBio **Sterile PVC Disposable Urine Cup** is made from medical-grade Polyvinyl Chloride (PVC). PVC is chosen for its excellent optical clarity (allowing easy visual inspection of the sample), chemical inertness (meaning it won't react with or leach substances into the urine), flexibility (making it less prone to breakage), and cost-effectiveness. It's also rigorously tested to be non-cytotoxic and free from common allergens like Latex and DEHP.

3. What sterilization method is employed for these **urine collection cup**?

Our **sterile urine cup** products typically undergo Ethylene Oxide (EO) sterilization. This is a highly effective, validated low-temperature sterilization method suitable for heat-sensitive materials like PVC. The process is strictly controlled and followed by an aeration phase to remove any residual EO gas, ensuring safety in accordance with ISO 11135 standards, achieving a Sterility Assurance Level (SAL) of 10-6.

4. How do **sterile urine cups** prevent contamination?

Contamination prevention is achieved through a multi-faceted approach: manufacturing in a controlled cleanroom environment, undergoing a validated sterilization process (e.g., EO sterilization), and being individually sealed in medical-grade packaging. The cups also feature a secure, leak-proof screw cap and a wide mouth opening designed to minimize spills and external exposure during collection and transport.

5. What are the key quality standards for urine specimen cups?

Key quality standards include ISO 13485 (Quality Management System for Medical Devices), CE marking (for products sold in the European Economic Area), and FDA registration (for products sold in the United States). Products should also meet specific test requirements such as sterility tests (USP ), endotoxin limits (USP ), and biocompatibility tests (ISO 10993 series or USP Class VI).

6. Can urine specimen cups be customized for specific needs?

Yes, PrisesBio offers various customization options for our **sterile urine cup** products, including different volume capacities, cap types, custom labeling (private label), specific packaging configurations, and in some cases, exploration of alternative medical-grade materials for unique applications. Please contact our sales team to discuss your specific requirements.

7. What is the typical shelf life of a **sterile urine cup**?

When stored under recommended conditions (dry, room temperature, away from direct sunlight), a **sterile urine cup** typically has a shelf life of 3 to 5 years from the date of manufacture. This information is usually indicated on the product packaging, along with the manufacturing and expiration dates.

References and Further Reading:

- Grand View Research. (2023). In-Vitro Diagnostics Market Size, Share & Trends Analysis Report By Product, By Technology, By Application, By End-use, By Region, And Segment Forecasts, 2023 - 2030. Retrieved from: https://www.grandviewresearch.com/industry-analysis/in-vitro-diagnostics-ivd-market

- ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes. Retrieved from: https://www.iso.org/standard/59752.html

- United States Pharmacopeia (USP). Sterility Tests. Retrieved from: (Specific link not publicly accessible without subscription, but can be referenced as USP official monograph)

- ISO 11135:2014 Sterilization of health care products — Ethylene oxide — Requirements for the development, validation and routine control of a sterilization process for medical devices. Retrieved from: https://www.iso.org/standard/55263.html

- Kaiser, D.L., & Young, J.G. (1993). Guidelines for the collection of urine specimens for culture and sensitivity. *Journal of Clinical Microbiology*, 31(1), 1-3. (While older, this foundational paper emphasizes sample integrity for urine culture). Retrieved from: https://journals.asm.org/doi/pdf/10.1128/jcm.31.1.1-3.1993

This is the last article

-

Sterile Urine Cup: Accurate Specimen Collection for Labs & Home

NewsAug.08,2025

-

Malaria Pf/Pan Ag Rapid Test Kit for Fast, Accurate Diagnosis

NewsAug.07,2025

-

Rapid Canine Corona Test: Fast & Accurate Results

NewsAug.06,2025

-

Rapid BZO Test Kit - Fast & Accurate Benzodiazepines Detection

NewsAug.04,2025

-

China Nylon Flocking Swabs - AI Enhanced Quality Collectors

NewsAug.03,2025

-

Highly Accurate hCG Pregnancy Test Strips - 5 Min Results

NewsAug.02,2025